If only a decade ago, the use of compressors was a luxury and something associated with large corporations, today it has become a necessity. No matter what type of business you run, it is a plain fact that having this piece of equipment plays a big part in the productivity and optimum performance of your business.

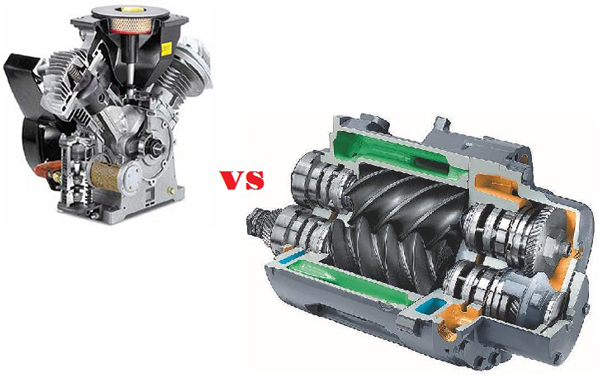

But, here is the big question: What type of air compressor to buy? Reciprocating or air screw compressor? Apart from having to choose between different suppliers/retailers and different brands, what makes the buying decision even harder is choosing the right model. Let’s go over particular features of both models.

Reciprocating Compressors

This type is used in various applications and features a heavy duty design, which is only one more of the many features that prove and ensure durability and long lifespan. The reciprocating compressor is usually used to enhance the performance of the working equipment used in severe duty working environments, and it is also ideal for higher gas-pressure applications.

The use of reciprocating compressors has started about 25 years ago (in the early 1990s), and ever since, both large and small air-cooled units have been available on the market with a single-acting design. This particular feature makes them cost-efficient and able to operate аt cooler temperatures, compared to other compressor types. The reciprocating compressor has high overall efficiency and it saves horsepower (hp) in no-load conditions. The only drawback is higher maintenance costs.

When it comes to compressed air applications of 150 psig or more, air screw compressors are the right choice to make. This model takes almost 50% оf the global air market and there is a good reason for that. Tougher performance, lower running costs and longer lifespan are the three key features of modern-day air screw compressors. The greatest thing about them is that they can fit any business project requirements, as their capacity varies from 4 to 450 kilowatts. Another huge advantage of the air screw compressor is that it runs on a lubricated air system, which makes its maintenance five times less expensive than the maintenance of compressors (reciprocating) that run on a non-lubricated air system.

Air screw compressors use water or oil for sealing and cooling. They offer maximum benefits and deliver the highest air volume when in compact spaces. Easy to install and cost-effective to maintain, the air screw compressor is definitely worth the purchase.