Crushing equipment is extensively used in the mining and construction industry for crushing different raw materials. Usually, the mining and construction applications require large rocks and ores to be crushed for further operation. There are different types of crushing machines on the market, and they are used for crushing specific hard materials. Whether by applying compressive force or a strong impact, the crushers reduce the size of large materials, and make them suitable for other applications. However, different applications require different types of crushing equipment. For example, the impact crushers are ideal for crushing materials which are later used in the construction of airports, highways, railways, etc., while the cone crusher is most commonly used in metallurgical, chemical, silicate and construction industry. The cone crusher and the impact crusher are definitely the most common crushers. Although used for the same purpose, they come with different specifications and configuration.

Cone Crusher

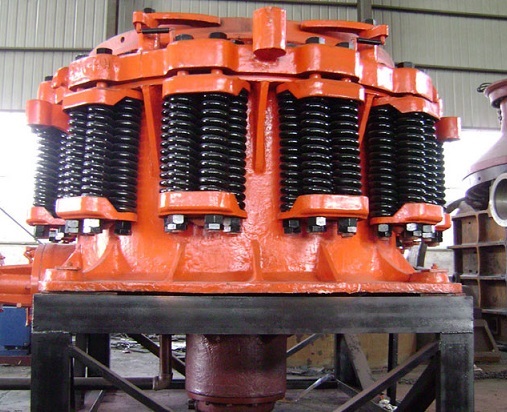

A cone crusher is a crushing machine suitable for crushing materials of medium hardness. It is known as a machine that provides high productivity and with unique crushing ability in both primary and secondary crushing processes. The cone crusher has a huge role in the construction industry, chemical industry, metallurgical industry and silicate industry. With high crushing ration and large capacity, the cone crusher is capable of crushing a variety of rocks and ores of medium hardness. A typical cone crusher has a motor, an eccentric shaft, an axle and a pair of bevel gear. The cone crusher crush the materials by pressing the materials between two walls. With low operating and maintenance costs, the cone crusher is a ideal choice when choosing between impact or cone crusher. Lastly, the cone crusher provides high-quality final products with desired size within a reduced cycle load.

Impact Crusher

The impact crusher is ideal for crushing materials with different hardness. Used as a secondary crusher, the impact crusher has higher reduction ratio (20:1) than the cone crusher, and it is one of the most commonly used rock crushers. It is very simple, efficient and reliable, used in the construction of airports, railways, highways, etc. The impact crusher is composed of an impact plate, a board hammer, a rotor, a feed hopper and few insignificant parts. The working principle of the impact crusher is very simple: the material is thrown to the impact plate and crushed until it can easily pass through the bottom opening or discharge gap. The discharge gap can be adjusted depending on the size that needs to be achieved.