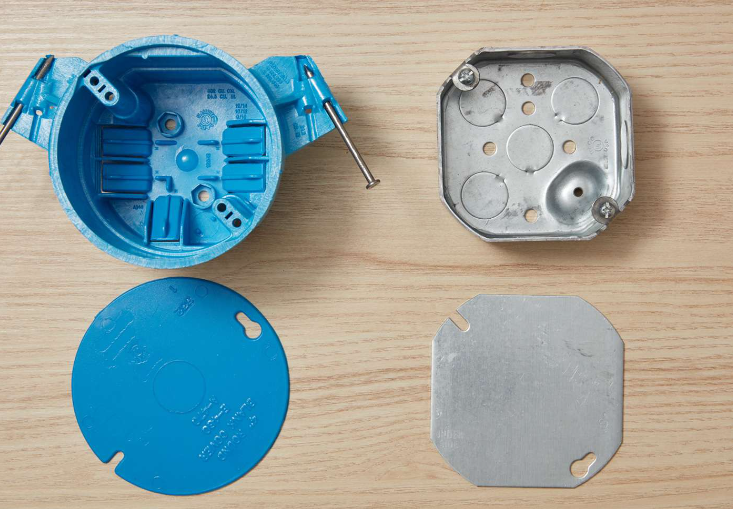

An electrical or junction box is the workhorse of electrical remodelling and repairing, serving as a junction or end point for electrical cables. Light switches, ceiling lights, fans, outlets and transition wires are just a few electrical elements installed in this type of box. While it’s available in many different shapes and sizes, the box is categorised as either plastic or metal.

In some cases, your choice will come down to personal preference, but in other cases the choice will be obvious due to grounding. Most DIY-ers prefer plastic, while certified electricians use both. Let’s see what the key differences are between the two.

Plastic Electrical Boxes

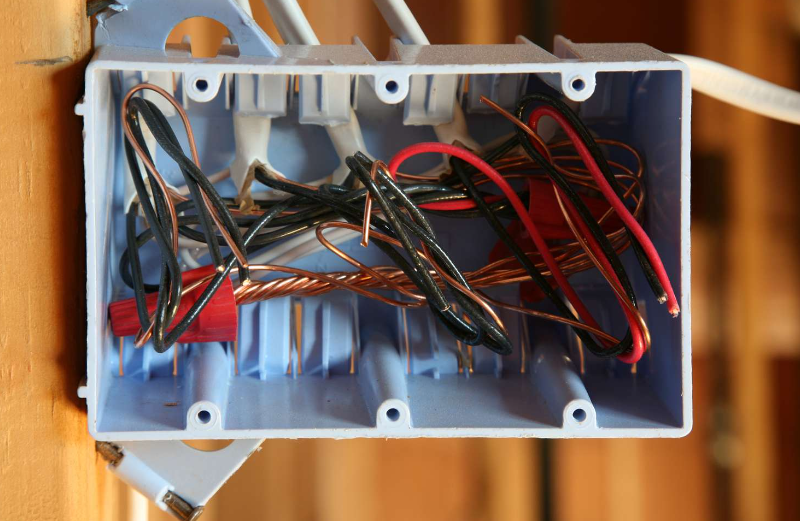

Generally made of PVC (polyvinyl chloride), the plastic junction boxes are quickly becoming the standard. This shouldn’t come as a surprise considering they are affordable, easy to work with, and lightweight. You can easily punch holes in them at the sides or back. However, PVC can melt at high temperatures, but it doesn’t conduct electricity. Many models come with built-in clamps, which further lowers the project cost.

Plastic boxes are recommended when using NM or Romex cables. Still, the code doesn’t require the use of NM cables. It’s important, though, that the application is grounded. Metal-sheathed wiring is dependent on the metal-sheathed wires with the metal box for grounding. This, however, doesn’t happen with plastic boxes, so if you don’t take any grounding measures, it can be very dangerous.

The plastic junction boxes are ideal for DIY-ers. They come with pre-attached nails you can nail into studs, and presets on the box indicate the thickness to help prevent nailing them face flush with the stud. Some models can be attached directly onto the drywall, and those are typically used when there’s no access to the stud.

Other models feature metal brackets that attach to the studs and are adjustable back and forth using a Phillips screwdriver. These are more expensive but provide the most flexibility, especially when the thickness of the wall is yet to be determined. Many home improvement stores favour the plastic alternative as it’s lighter, has softer edges, and has holes that are easier to knock out.

Moreover, many models feature doors that act as clamps to hold the cable to the box, removing the need for using extra clamps. The biggest downside is that they have the tendency to lose shape when stressed, regardless of whether it’s due to heat or impact. And while the pre-attached door clamps are convenient, they hold the cable in place even when you want to remove it.

Metal Electrical Boxes

Believe it or not, metal electrical boxes were used long before the plastic were introduced. Metal is a top choice because it’s very strong, fireproof and can’t be melted, offering the greatest level of security for every electrical application. On the other hand, plastic boxes can twist even when slightly stressed, and with enough stress, they’ll distend.

In fact, even if you stud a plastic j box the wrong way you can twist it out of shape. It’s virtually impossible to do these things to a metal. However, for the average DIY-er, a metal box can be more difficult to work with, as it has rear and side knock-outs that need supplementary clamps.

In addition, the sharp edges can take a toll on your hands, which is why it’s recommended you use gloves when working with this option. Metal j boxes are used when metal-sheathed cables and conduits are running in and out of the box. The cable and conduit depend on the contact from the metal sheathing to the metal box to complete the grounding. Moreover, metal boxes are ideal for interior exposed applications.

Generally, the boxes are recessed in walls, but some areas, like mudrooms or unfinished basements, may not have a complete wall you can install them in, in which case the box is attached directly to the masonry wall. As the wires will be exposed, the metal conduit is necessary.

Metal boxes can be used with NM and Romex wiring, but you need to take extra precautions to ensure grounding. Any contact between the box and the attached device will complete the grounding contact. Even if the ground is not complete, NM and Romex wiring can still be used by attaching the green or bare grounding wire to the box with the help of a screw.

Conclusion

Both metal and plastic junction boxes find use in different applications. They have distinct advantages and disadvantages, and you should choose based on your specific demands and the demands of the application.

For most, plastic boxes are the preferred option as they’re easier to work with, and are more affordable, whereas others prefer metal boxes due to their toughness and the reduced need for grounding solutions. At the end of the day, you’ll find both types in a wide range of shapes and sizes, suitable for any application you might need.