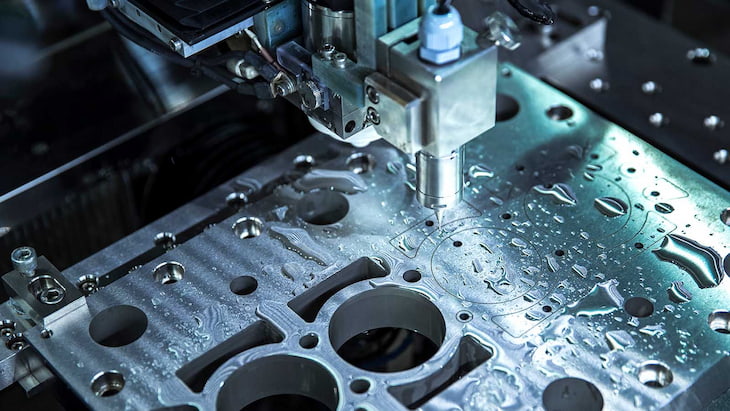

In the realm of manufacturing and fabrication, Computer Numerical Control (CNC) machinery has emerged as a transformative force, redefining precision and efficiency across various industries. From automotive and aerospace to healthcare and consumer electronics, CNC machines have become indispensable in creating intricate components with unparalleled accuracy. At the heart of this technological revolution lies the crucial role played by CNC machine software, a key element that drives the performance and precision of these cutting-edge machines.

The Significance of CNC Machinery in Fabrication:

CNC machinery has revolutionized the way manufacturers approach the production of intricate components and prototypes. Unlike conventional manual machining processes, CNC machines operate through programmed commands, allowing for precise and repetitive tasks with minimal human intervention. This level of automation not only enhances accuracy but also significantly reduces production time and costs.

Industries such as aerospace and automotive rely heavily on CNC machining to produce complex components, where precision is paramount. The medical sector benefits from CNC technology in the creation of custom implants and prosthetics, showcasing the versatility of these machines across diverse applications. Additionally, CNC machinery has found its way into the consumer electronics sector, where intricate parts are seamlessly produced with high precision.

The Role of CNC Machine Software

While the hardware of CNC machines provides the mechanical backbone, it is the CNC machine software that acts as the brain, converting design specifications into precise movements. CNC software interprets the digital designs, known as Computer-Aided Design (CAD) files, and translates them into a language the CNC machine understands. This intricate process ensures that the final product mirrors the intended design with meticulous accuracy.

One of the industry-leading CNC machine software solutions that has gained prominence is FastCAM V8. This software plays a pivotal role in enhancing the functionality and efficiency of CNC machines, setting new standards in the world of computer-controlled machining.

FastCAM V8: A Pioneer in CNC Machine Software

FastCAM V8 stands out as a trailblazer in the realm of CNC machine software, offering a comprehensive suite of features that cater to the diverse needs of manufacturers. Its significance lies not only in its ability to generate intricate toolpaths but also in its user-friendly interface, making it accessible to both seasoned professionals and those new to CNC machining.

Intuitive User Interface

FastCAM V8 boasts an intuitive user interface, streamlining the process of translating design concepts into executable commands for the CNC machine. This user-friendly approach enhances efficiency, reducing the learning curve for operators and empowering them to harness the full potential of CNC technology.

Versatility in File Compatibility

One of the standout features of FastCAM V8 is its compatibility with a wide range of file formats. Whether it’s DXF, DWG, or even PDF, the software seamlessly imports and translates these files into CNC machine instructions. This versatility ensures that designers and engineers can work with their preferred design software without facing compatibility issues.

Optimized Nesting and Material Utilization

FastCAM V8 excels in optimizing material usage through efficient nesting algorithms. By minimizing waste and maximizing the use of available materials, the software contributes to cost savings and sustainability—an essential consideration in today’s manufacturing landscape.

Dynamic Toolpath Generation

The software’s dynamic toolpath generation capabilities allow for intricate and efficient cutting strategies. This ensures that CNC machines equipped with FastCAM V8 produce components with the highest precision and in the shortest possible time, optimizing overall production efficiency.

Adaptability to Different CNC Machines

FastCAM V8 is designed to be compatible with a wide range of CNC machines, making it a versatile choice for manufacturers utilizing different equipment. This adaptability ensures that companies can seamlessly integrate FastCAM V8 into their existing CNC setups, enhancing their machining capabilities without significant infrastructure changes.

Mach3: A CNC Software Powerhouse

Developed by ArtSoft, Mach3 has carved a niche for itself in the CNC software landscape, offering a comprehensive suite of features that cater to the diverse needs of manufacturers across various industries.

Real-Time Control

At the heart of Mach3’s appeal is its real-time control capabilities, providing operators with a responsive and dynamic interface. This feature allows for seamless adjustments and modifications during the machining process, ensuring precision and accuracy in real-time. Manufacturers appreciate the flexibility offered by Mach3, as it enables them to adapt to changing requirements and fine-tune parameters on the fly.

Customization and Flexibility

Mach3 stands out for its extensive customization options, allowing users to tailor the software to their specific needs. This flexibility is particularly beneficial for manufacturers with unique machining requirements or specialized projects. From defining toolpaths to adjusting speed and feed rates, Mach3 empowers operators to customize the software according to the intricacies of their machining tasks.

Handling Complex Machining Tasks

Mach3 excels in handling complex machining tasks with precision. Whether it’s intricate designs, 3D contours, or multi-axis machining, the software proves its mettle in diverse applications. This capability makes Mach3 a preferred choice for industries where precision and intricacy are paramount, such as aerospace, medical, and automotive manufacturing.

Compatibility and Integration

Mach3 is designed to seamlessly integrate with a wide range of CNC machines, making it a versatile choice for manufacturers with different equipment. Its compatibility with various hardware configurations ensures that users can leverage Mach3 across their existing CNC setups, minimizing the need for significant infrastructure changes. This adaptability contributes to the software’s widespread adoption across diverse manufacturing environments.

Learning Curve and Operator Expertise

While Mach3 offers robust features, it’s important to note that the software may have a steeper learning curve compared to some other CNC solutions. Operators may need to invest time in mastering the intricacies of Mach3 to unlock its full potential. However, for those with a solid understanding of CNC machining principles and a willingness to delve into the software’s capabilities, Mach3 becomes a powerful tool for achieving precision and control.

Community Support and Resources

A strong community of users surrounds Mach3, providing valuable support and resources for both beginners and experienced operators. Online forums, tutorials, and user communities contribute to the software’s ecosystem, fostering collaboration and knowledge-sharing. This support network enhances the overall user experience and facilitates a smoother learning curve for those new to Mach3.

Conclusion

As CNC machinery continues to shape the landscape of modern fabrication, the role of CNC machine software cannot be overstated. FastCAM V8 stands out as a beacon of innovation in this space, providing manufacturers with a powerful tool to optimize their CNC processes. Its intuitive interface, file compatibility, nesting efficiency, dynamic toolpath generation, and adaptability to various CNC machines position it as a leader in the industry.

In the dynamic world of CNC machining, where precision and efficiency are paramount, FastCAM V8 paves the way for a new era of possibilities. As industries evolve and demand ever-increasing levels of accuracy, CNC machine software like FastCAM V8 will play a pivotal role in driving progress and shaping the future of fabrication.