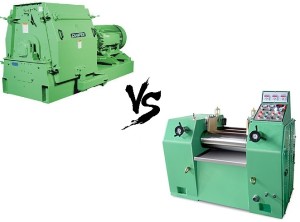

The hammer mill is considered as the N.1 choice when a grinding machine for size reduction is required. In the past, the roller mill was the most economical and efficient grinding machine. Today, those who are involved in the businesses that depend on material size reduction have the choice of using either hammer mill or roller mill, or maybe both. However, there are many factors that may affect their choice.

One very important factor is the power consumption. The diameters of the hammer mill are gradually increased, allowing a greater peripheral beater tip speed at lower revolutions. This means that the impact on the materials in the grinding chamber is bigger. So, the power consumption of the hammer mill has been reduced to minimum. This is mainly because of the combination of increased screen diameter and increased peripheral beater tip speed.

The hammer mill relies heavily on the screen impact in order to reduce the size of the material to the desired granularity level. The roller mill simply “rolls & crushes” the material between its two or more rotating cylinders. The principle of the roller mill is more simple and it consumes significantly less power, but it doesn’t produce better final product when compared with a hammer mill. The screen-hole diameter of the hammer mill allows better control over the final product quality.

The hammer mill doesn’t require a lot of care and attention, unlike the roller mill which needs lots of attention in order to achieve an accurate and consistent grind. One big disadvantage (and maybe the only one) of the hammer mill is that it uses only little or no air flow at all for efficient operation. The roller mill, on the other hand, does not require a steady and well-balanced airflow for efficient operation. The costs of moving that air includes the costs for filters and fans.